Unlock Ideal Efficiency With Comprehensive Strapping Machine Service and Upkeep

Strapping machines play a vital duty in packaging operations. Their performance directly affects performance and performance. Numerous companies neglect the relevance of routine service and upkeep. This oversight can bring about raised downtime and higher repair service costs. Understanding the essential advantages of a positive upkeep approach is very important. As organizations seek to boost their operations, checking out comprehensive care choices comes to be required. What actions can be taken to guarantee peak performance?

The Value of Routine Servicing for Strapping Machines

Key Benefits of a Proactive Maintenance Technique

A positive upkeep strategy uses considerable benefits for strapping machines - strapping machine service. By prioritizing normal maintenance, companies can achieve raised tools durability, enhance operational effectiveness, and lessen dangers connected with downtime. These benefits add to a much more trustworthy and efficient packaging process

Enhanced Equipment Long Life

Applying a positive maintenance method considerably improves the long life of strapping machines. By consistently servicing and evaluating devices, prospective concerns can be determined and addressed prior to they escalate into costly fixings or failings. This strategy lessens wear and tear, making certain that all elements operate successfully over time. Additionally, routine upkeep assists keep the honesty of crucial parts, reducing the possibility of unanticipated breakdowns. Consequently, organizations can expand the functional life expectancy of their strapping machines, maximizing their financial investment. In addition, well-maintained devices is less vulnerable to unexpected breakdowns, enabling a more steady manufacturing environment. Inevitably, a commitment to proactive maintenance not only preserves devices long life but also fosters dependability and uniformity in product packaging operations.

Improved Operational Performance

When companies prioritize positive upkeep for strapping machines, they frequently experience substantial improvements in functional performance. This method warranties that tools runs at peak efficiency levels, minimizing the possibility of unforeseen problems that interfere with process. Consistently set up upkeep permits for prompt identification and rectification of possible issues, resulting in smoother procedures. Well-maintained machines need much less power and resource intake, contributing to general price financial savings. By guaranteeing that strapping machines are regularly in leading problem, businesses can boost throughput, enhance item high quality, and enhance employee performance. Inevitably, this proactive technique fosters a much more streamlined operation, enabling business to satisfy consumer needs efficiently and preserve a competitive side in the market.

Lowered Downtime Threats

Positive upkeep substantially lowers the risks of downtime associated with strapping machines. By regularly servicing and inspecting devices, possible concerns can be identified and addressed prior to they rise into critical failings. This method lessens unexpected malfunctions, ensuring that production schedules continue to be uninterrupted. Furthermore, with a properly maintained strapping machine, operators experience enhanced integrity and efficiency, which adds to total functional connection. Set up maintenance additionally enables the effective use of sources, decreasing the demand for emergency repair services that can be taxing and expensive. Consequently, businesses profit from enhanced performance and a much more streamlined operations. Ultimately, purchasing aggressive maintenance results in a significant decrease in downtime threats, promoting a more resistant manufacturing atmosphere.

Common Issues That Occur From Disregarding Maintenance

Ignoring upkeep on strapping machines can bring about a myriad of problems that ultimately interrupt procedures. One typical trouble is the build-up of dirt and particles, which can create mechanical parts to jam or wear too soon. In addition, failure to lubricate relocating parts might lead to boosted friction, causing getting too hot and potential break downs. Imbalance of components usually happens without regular adjustments, causing poor strapping high quality and wasted materials. Furthermore, electrical parts can deteriorate otherwise checked on a regular basis, leading to irregular efficiency or complete failing. These concerns not just concession production effectiveness yet additionally enhance repair service costs, highlighting the relevance of consistent maintenance to ensure peak machine capability and long life.

Specialist Care: Just How Expert Services Enhance Devices Durability

Expert services play a crucial duty in prolonging the life expectancy of strapping machines via targeted maintenance strategies. strapping machine service. By applying preventative actions, these professionals not just minimize the chance of equipment failing yet likewise improve total functional performance. Furthermore, their troubleshooting methods allow speedy identification and resolution of issues, making certain machines remain in peak condition

Lengthening Tools Lifespan

Preventative Upkeep Advantages

Preventative upkeep uses substantial benefits for the durability and effectiveness of strapping machines. By carrying out regular inspections and maintenance, drivers can determine potential concerns before they intensify right into pricey failures. This positive technique not just extends the life expectancy of the equipment yet additionally improves its performance, guaranteeing reputable and regular procedure. Furthermore, preventative maintenance reduces downtime, enabling organizations to keep productivity while reducing repair work costs connected with emergency malfunctions. Expert services give competence click now in preserving suitable maker problems, utilizing specialized knowledge to deal with particular wear and tear. Ultimately, purchasing preventative upkeep safeguards tools integrity, cultivates operational efficiency, and sustains an extra sustainable company design, contributing to overall expense savings and enhanced productivity.

Specialist Troubleshooting Techniques

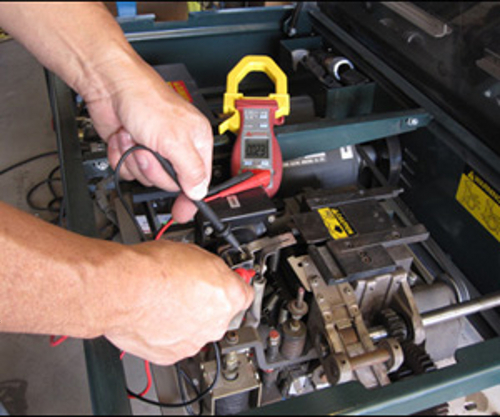

Reliable repairing strategies are vital for dealing with unexpected issues that can occur during the procedure of strapping machines. Experts learnt these methods utilize organized approaches to recognize and resolve problems efficiently. They begin by assessing error codes and equipment performance information, which helps limit potential fault locations. Next off, they check parts, such as electric motors, belts, and sensing units, to find wear or misalignment. Making use of advanced analysis devices, they can pinpoint problems that might not be instantly visible. Furthermore, their knowledge permits them to advise corrective actions, making certain very little downtime. By utilizing these professional fixing methods, drivers can boost devices durability and preserve peak efficiency, inevitably resulting in enhanced productivity and minimized functional prices.

Developing a Personalized Upkeep Set Up

A well-structured maintenance routine is vital for guaranteeing the optimal efficiency and durability of strapping machines. To develop a customized routine, operators need to initially examine the maker's usage patterns, determining high-demand durations and prospective stress factors. Regular examinations ought to be set up based on producer referrals, while additionally thinking about real functional conditions. Secret jobs might consist of cleansing, lubrication, and parts substitute, tailored to the specific model and application. In addition, recording upkeep tasks permits fad evaluation, helping to lessen and predict future requirements downtime. Involving with solution professionals can supply insights into ideal techniques and needed adjustments, making sure that the maintenance schedule develops together with the machine's efficiency and operational demands. This proactive strategy inevitably boosts effectiveness and reliability.

Purchasing Training for In-House Upkeep Teams

Training programs for in-house upkeep teams play a vital role in making the most of the efficiency and reliability of strapping machines. By equipping staff member with specialized skills, companies can assure that maintenance and troubleshooting are performed properly and quickly. Educated staff can recognize potential problems prior to they intensify, reducing downtime and upkeep expenses. In addition, training cultivates a much deeper understanding of the equipment, allowing teams to apply best practices for procedure and treatment. This investment not only boosts the performance of strapping machines yet likewise improves team spirits and self-confidence, bring about a more aggressive upkeep culture. Eventually, focusing on training will yield considerable lasting benefits, guaranteeing peak efficiency and expanding the lifespan of strapping devices.

Often Asked Questions

Exactly How Usually Should Strapping Machines Be Serviced?

Strapping machines need to generally be serviced every six months to ensure peak performance. Routine maintenance checks help identify concerns early, lengthen the equipment's life expectancy, and preserve regular strapping high quality and performance in production procedures.

What Are the Indications That Maintenance Is Needed?

Signs that upkeep is required include unusual sounds, inconsistent strapping high quality, constant jams, mistake messages on the display screen, and noticeable endure parts (strapping machine service). Addressing these concerns without delay can stop further damage and assurance effective operation

Can I Perform Maintenance Without Expert Assist?

Yes, people can execute read this article basic upkeep on equipment, such as cleansing and inspecting parts. However, for complicated concerns, expert support is advised to assure safety and security and appropriate performance, protecting against potential damages or operational failures.

What Parts Typically Require Substitute Throughout Servicing?

During maintenance, typically use this link changed parts consist of belts, blades, sensing units, and springtimes. Routine assessment of these parts warranties peak capability and prolongs the lifespan of strapping machines, stopping unforeseen malfunctions and boosting total effectiveness.

Just How Can I Track My Machine's Upkeep History?

To track a maker's upkeep background, one can use logbooks, electronic tracking software, or upkeep management systems that tape solution dates, executed jobs, and changed components, guaranteeing comprehensive oversight of the device's operational condition.

Carrying out a positive maintenance technique greatly enhances the longevity of strapping machines. Ignoring maintenance on strapping machines can lead to a myriad of issues that ultimately disrupt procedures. Preventative upkeep provides considerable benefits for the longevity and efficiency of strapping machines. A well-structured maintenance timetable is important for guaranteeing the optimal performance and durability of strapping machines. Educating programs for internal maintenance teams play a crucial role in making the most of the efficiency and reliability of strapping machines.